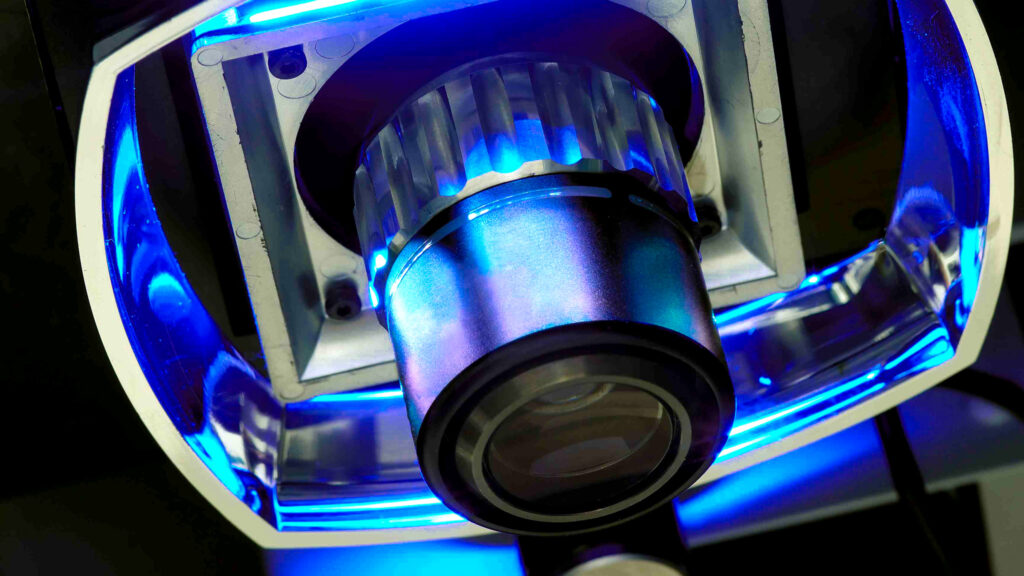

Ring welding test bench for small production and laboratory development

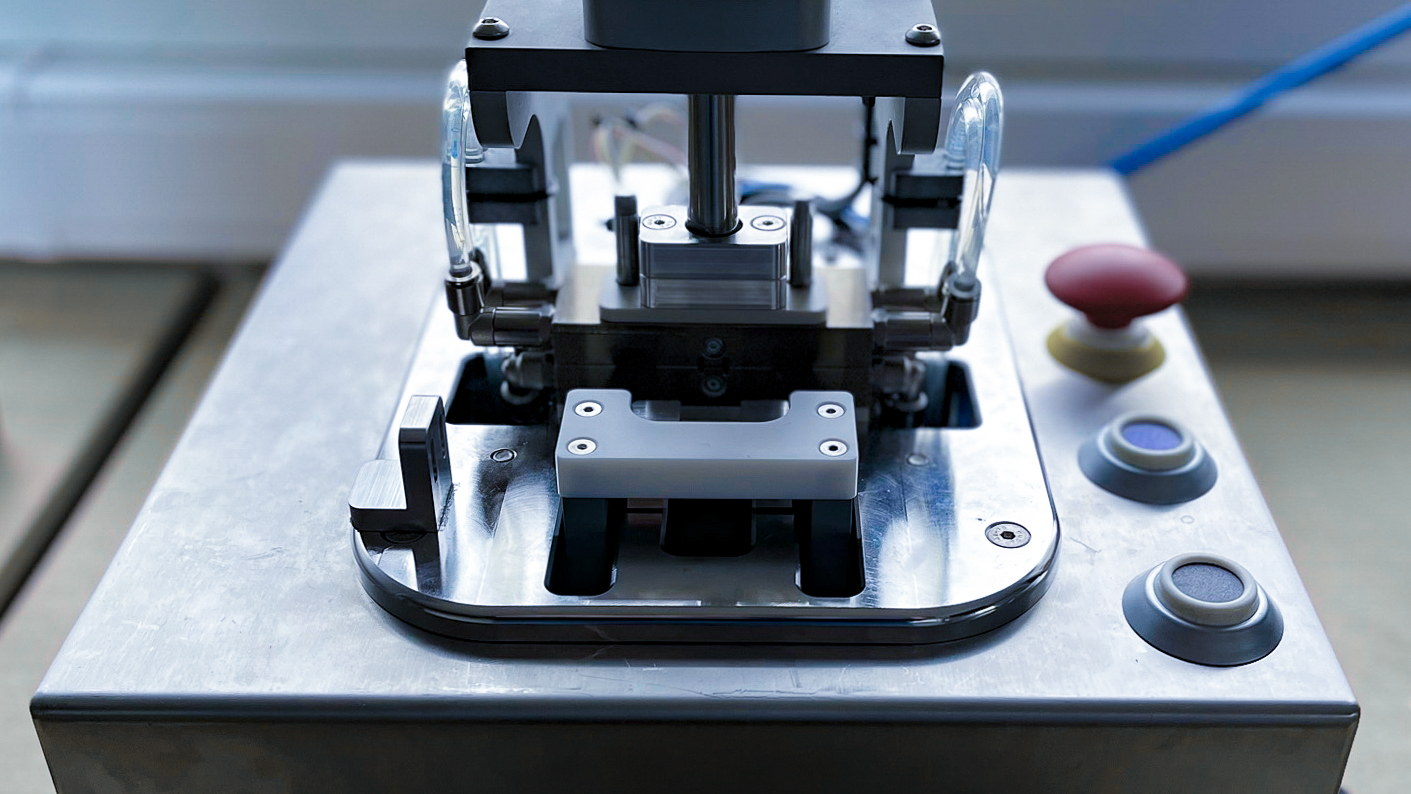

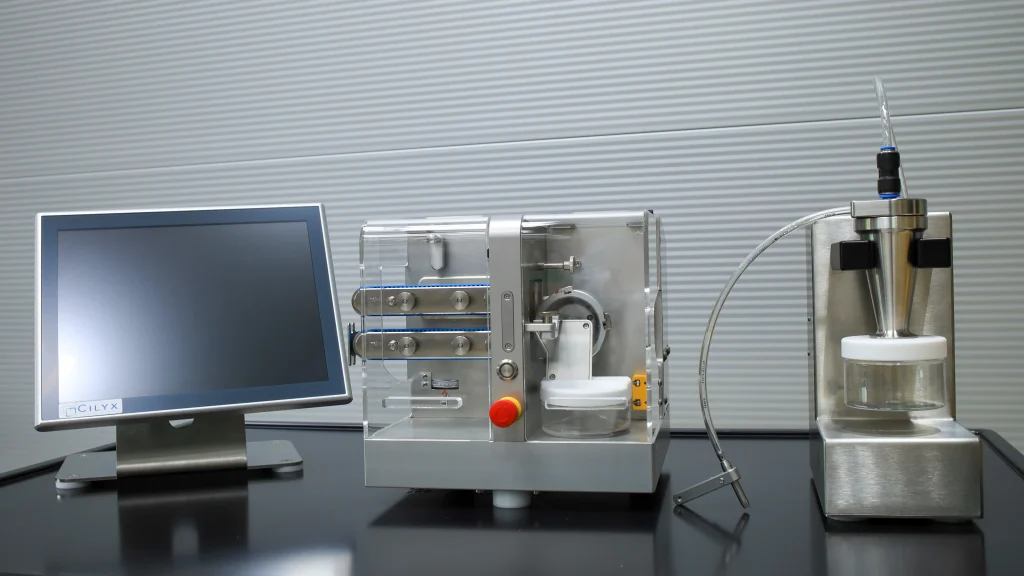

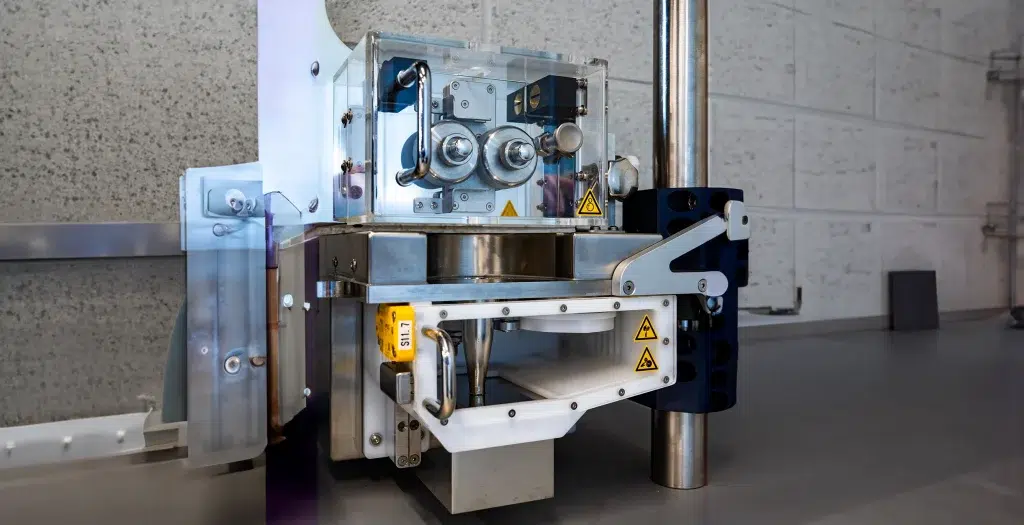

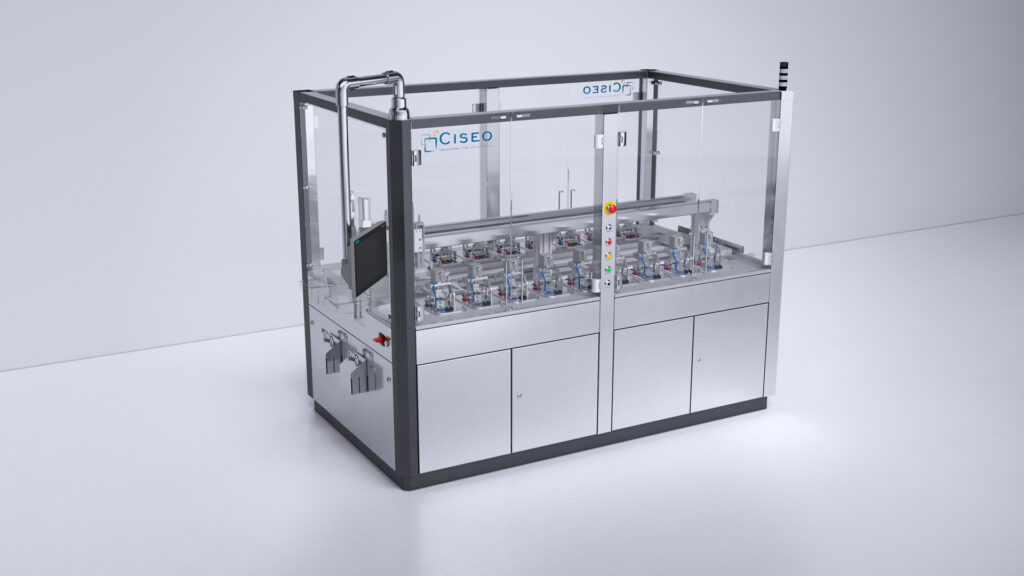

Cilyx has developed an innovative welding process for polymer strands. It is particularly well adapted to the production of vaginal rings. Process parameters are fully adjustable for various applications and materials (temperature, cycle time, etc.). The welding test bench is easily configurable to customer needs and is particularly adapted for process development, lab production and small scale semi-automatic production.

Cilyx’s ring welding test bench perfectly meets the needs of the pharmaceutical laboratories : robust, highly configurable, compact and easy to handly.

It increases your laboratory’s productivity while guaranteeing the safety of your operators. It helps your teams to drastically reduce the development time.

CE certified, it meets all the requirements of cGMP.