Industry

Industry

Production Systems

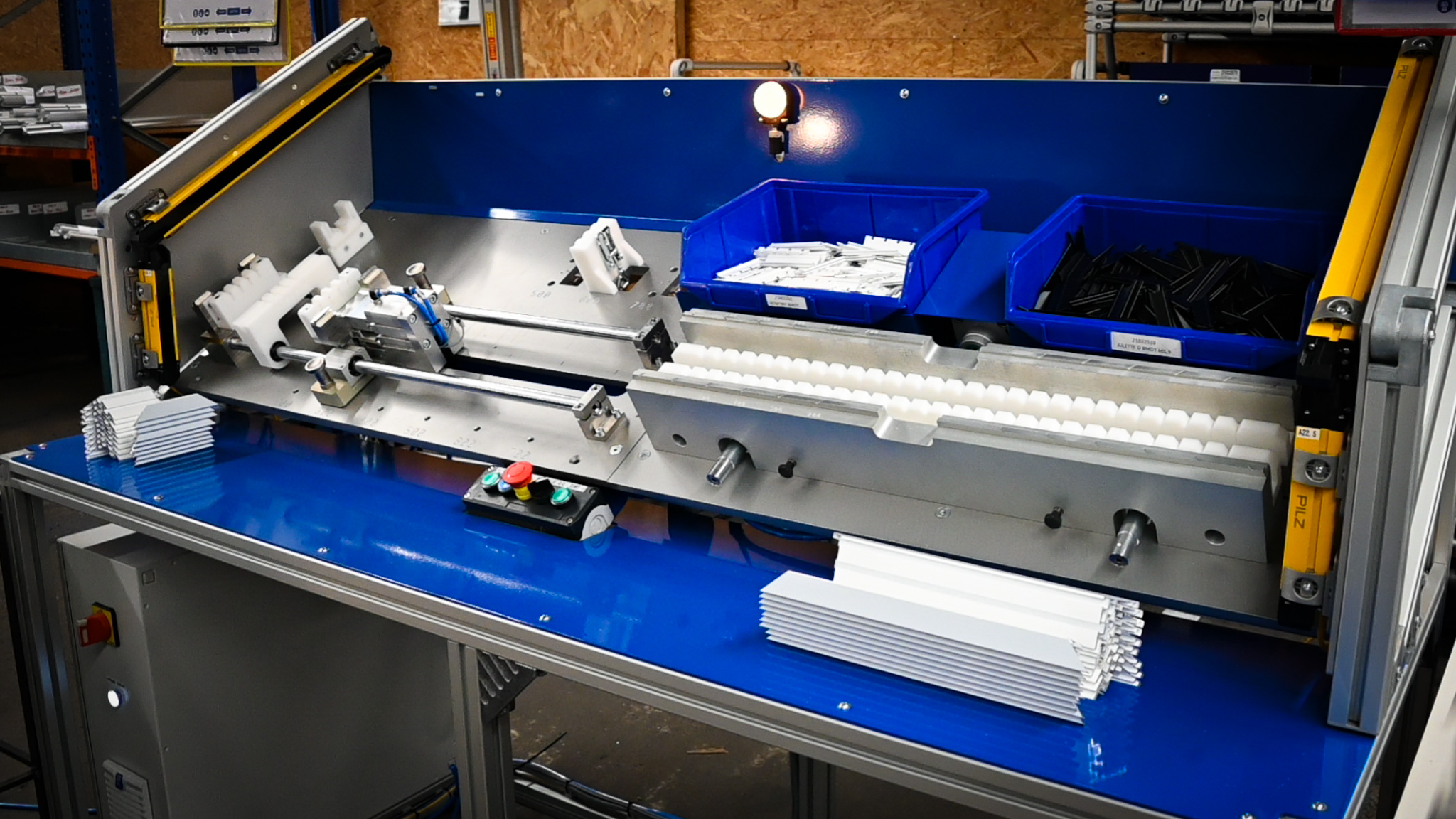

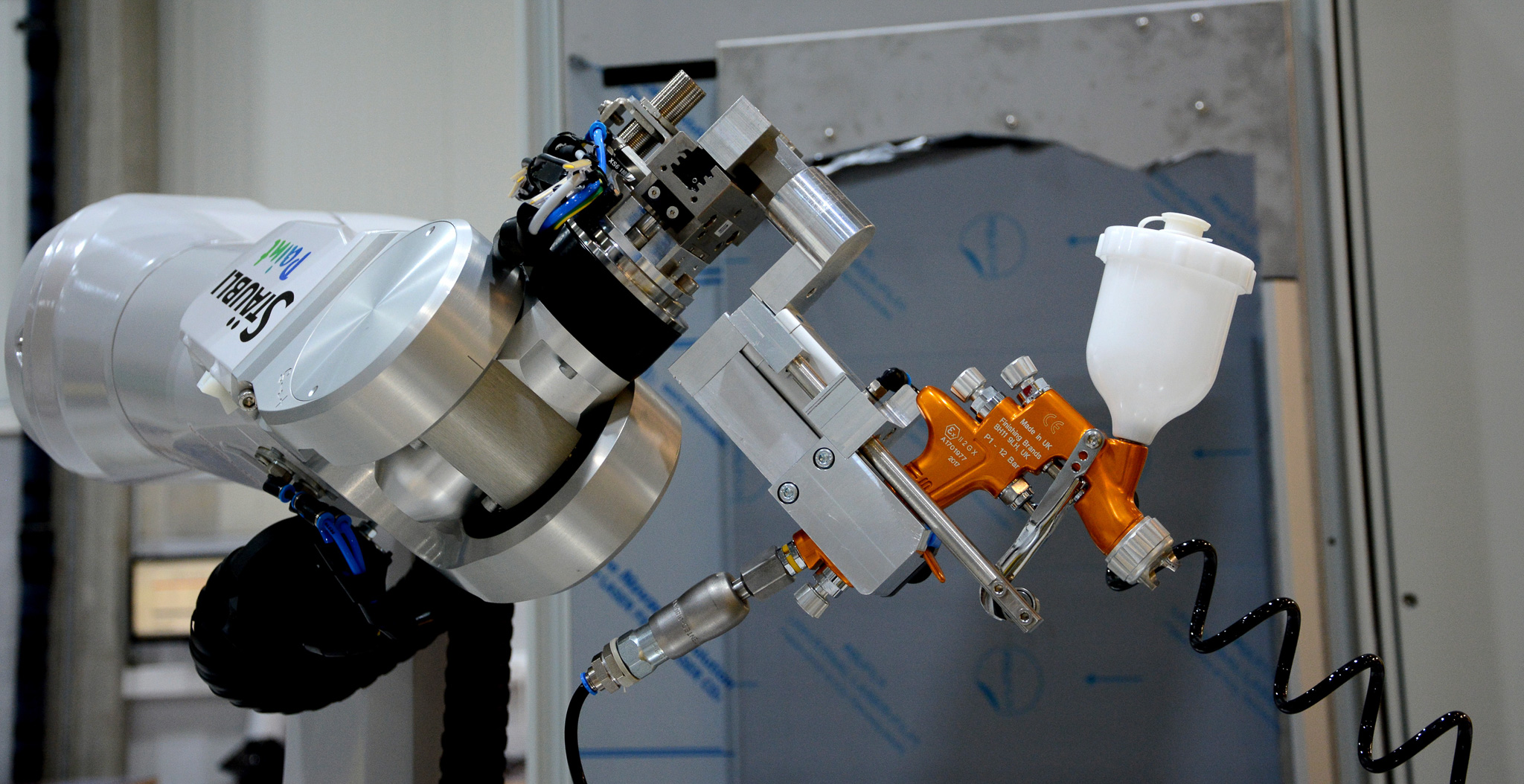

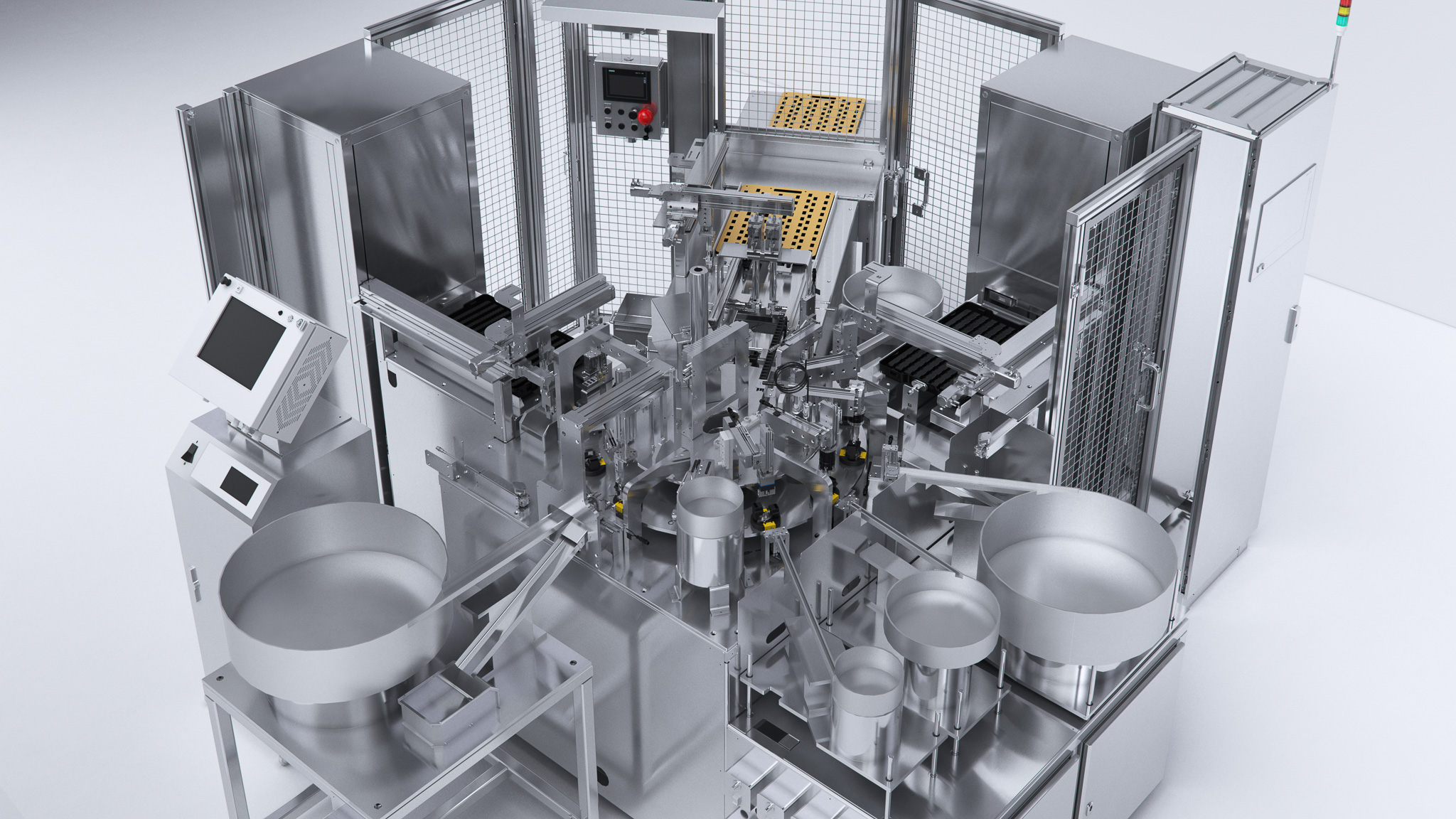

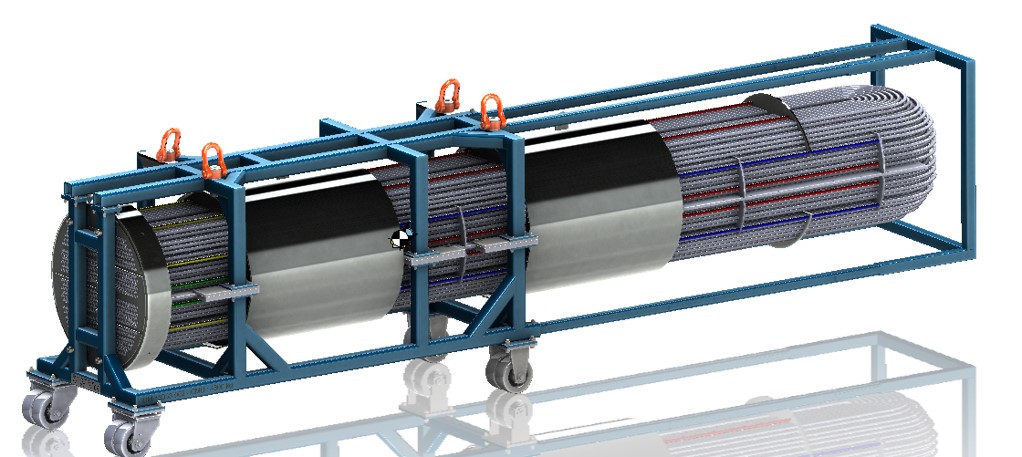

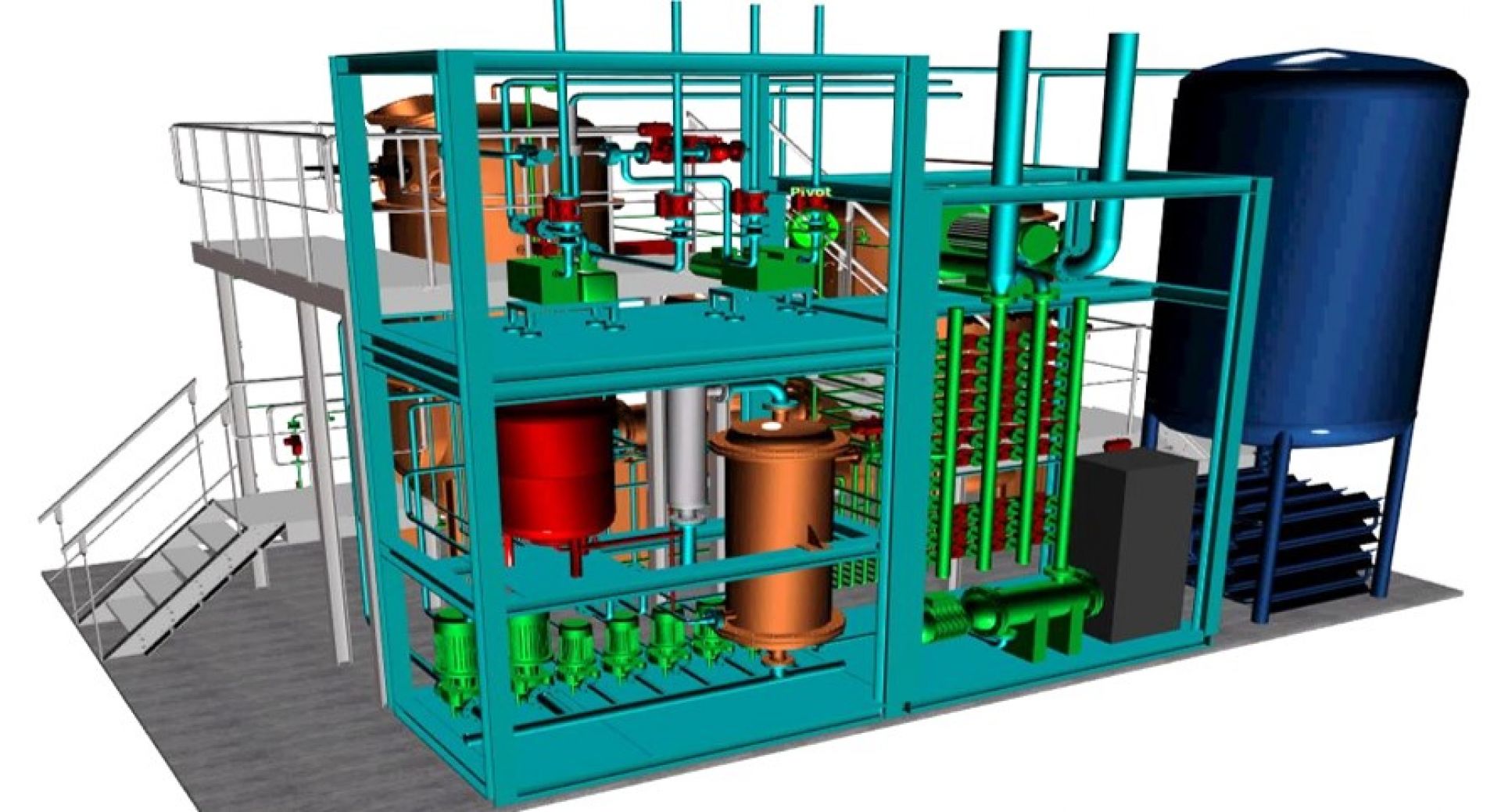

A production system is a set of processes and resources that are used to create goods or services. These systems can be designed to be efficient, flexible, and responsive to changes in demand or market conditions.

There are several different types of production systems. The specific type of production system used in a given situation depends on a variety of factors, including the nature of the product or service being produced, the level of customization required, and the level of demand for the product.

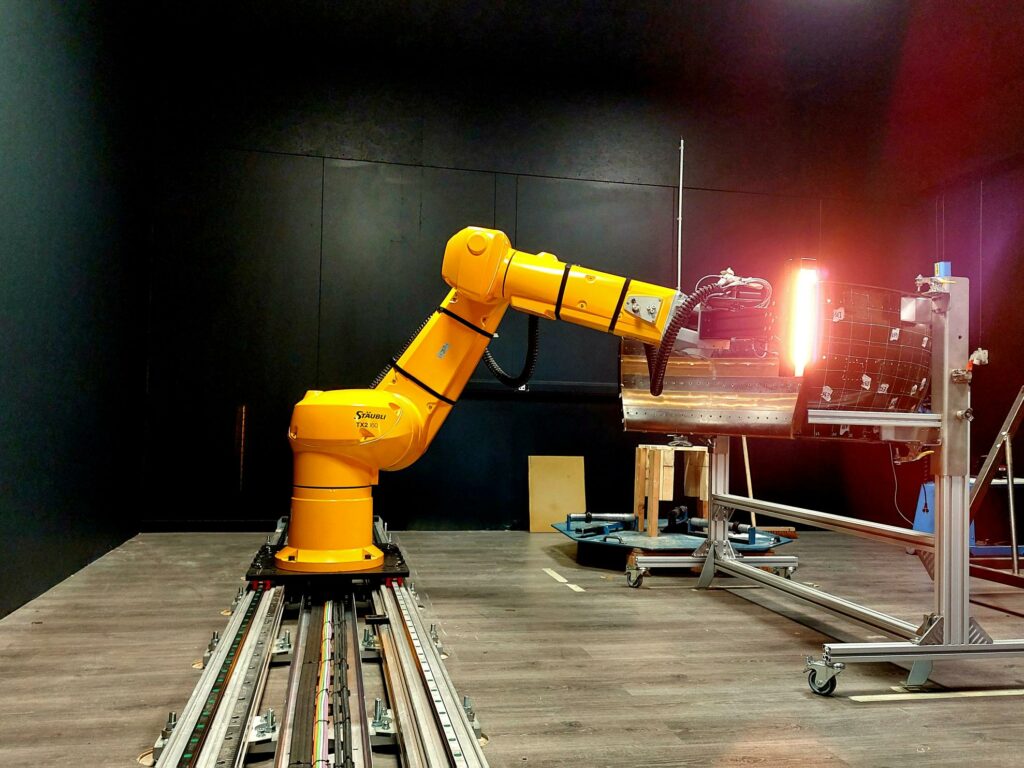

Cilyx develops and integrates “turnkey” production systems and equipment. Thanks to its engineering office and its workshop, Cilyx integrates, tests and qualifies its solutions prior to delivery. Cilyx also develops complex solutions in automated industrial processes thanks to its skills in automation, robotics, electricity, instrumentation, industrial IT and artificial vision.

Test & Measurement Solutions

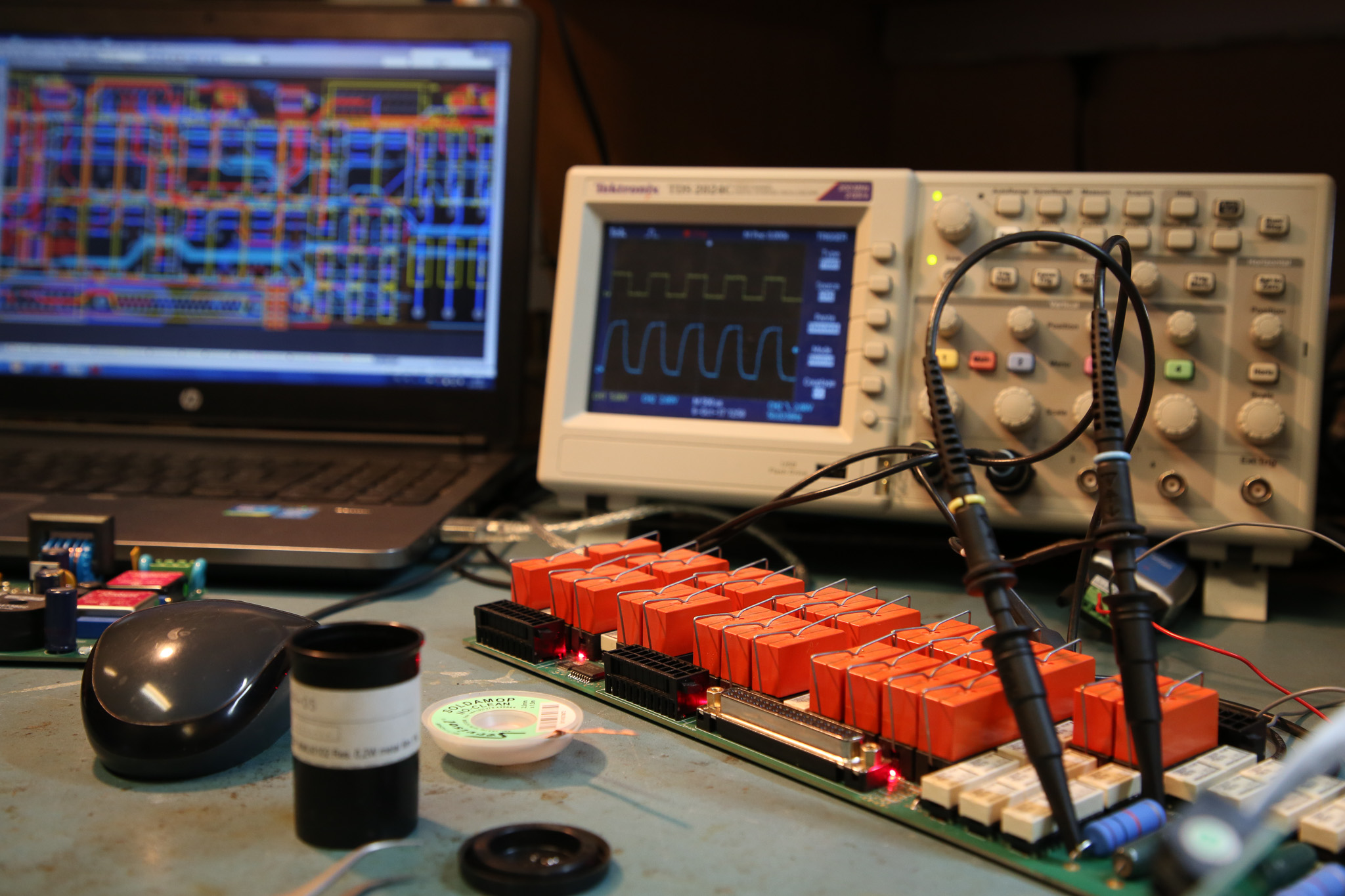

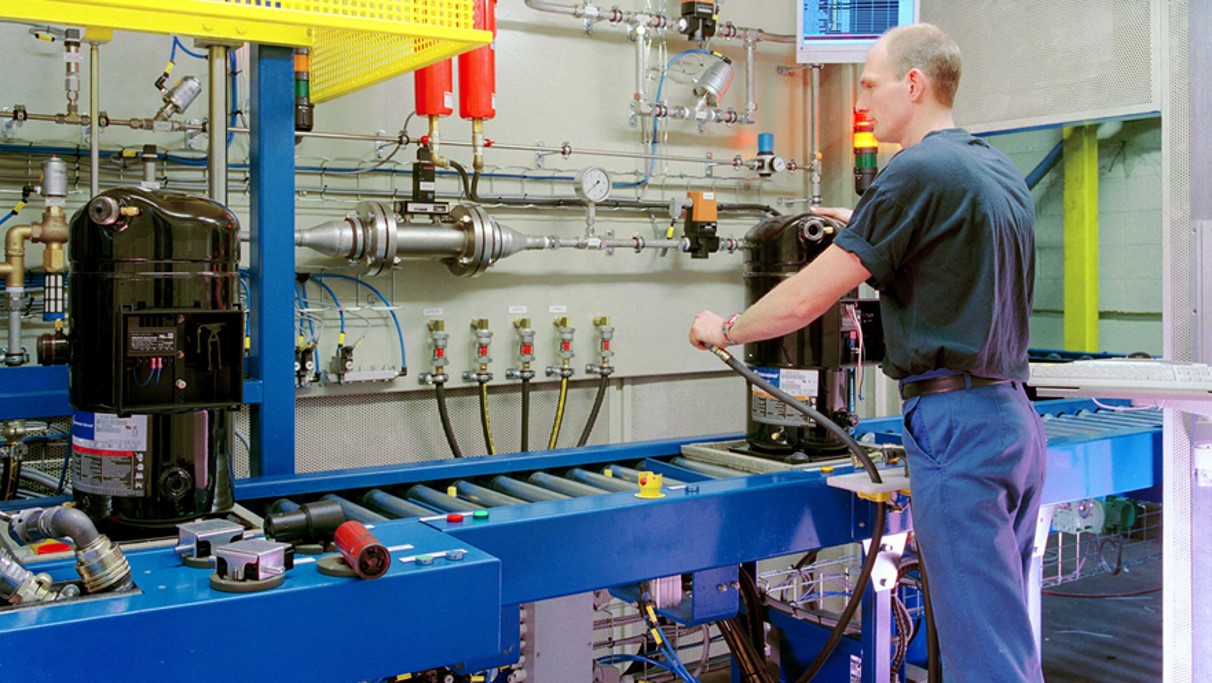

A test bench or test bed is a specialized workstation or platform that is used to test the performance or functionality of a product or system. Test benches are commonly used in a variety of industries, including electronics, automotive, aerospace, and manufacturing.

Test benches typically include a set of specialized tools and instruments, such as oscilloscopes, multimeters, and data acquisition systems, which are used to measure and analyze various aspects of the product or system under test. Test benches may also include environmental controls, such as temperature and humidity chambers, to simulate different operating conditions.

Test benches can be used to perform a wide range of tests, including functional tests, stress tests, and performance tests. They are often used to troubleshoot problems, verify compliance with standards or regulations, and optimize the design of a product or system.

Overall, test benches are an essential tool for ensuring the quality and reliability of products and systems, and they play a critical role in the development and testing process.

Over the years, Cilyx has acquired significant experience in the field of test-bed design and production for industrial equipment or systems. These custom-built test beds integrate the latest technology in mechanics, control-command systems, or data acquisition. Often equiped with hundreds of measuring lines, these test beds constitute efficient systems used within the framework of industrial development and production programmes .

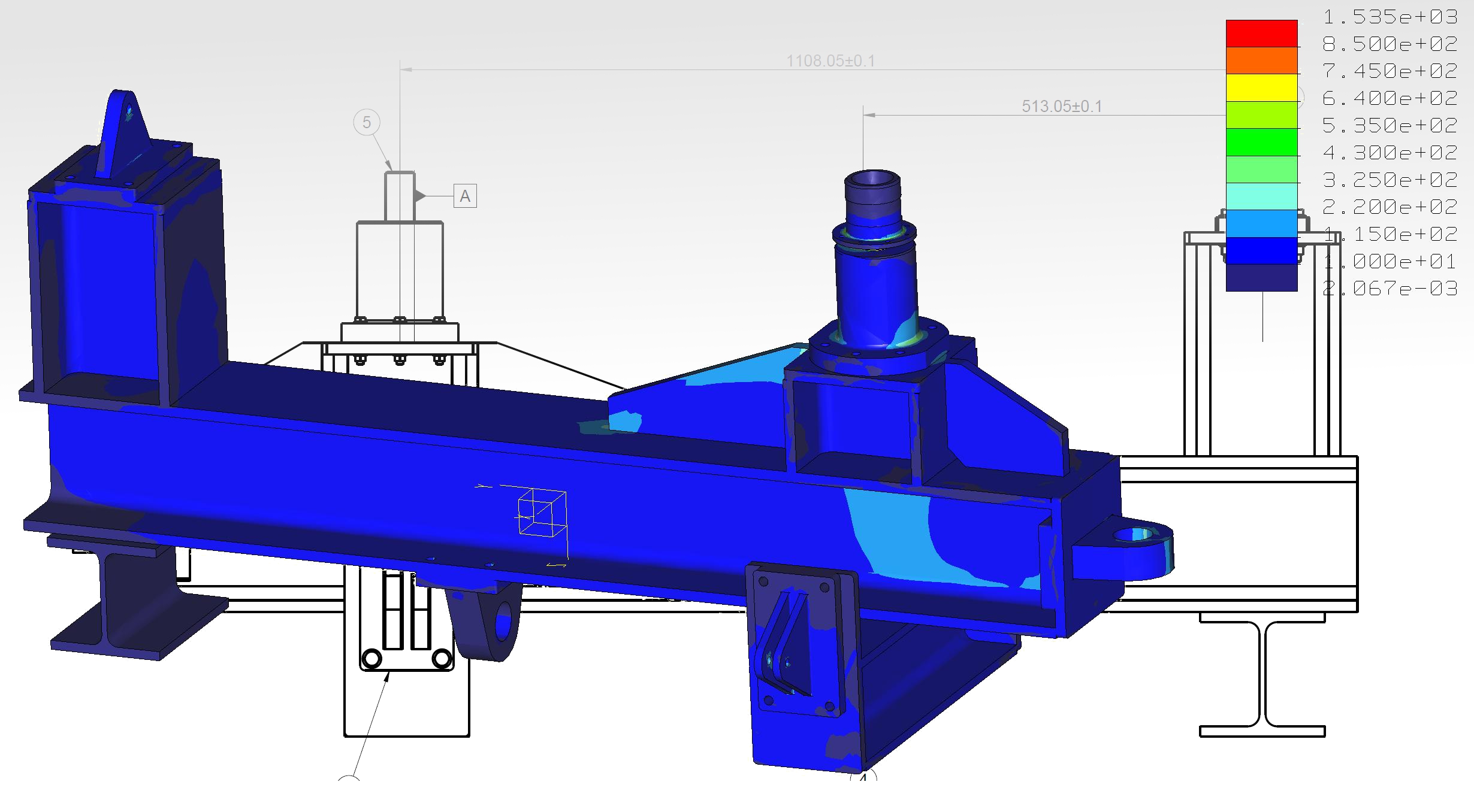

Mechanical Engineering

Engineers and consultants are professionals who use their expertise to solve technical problems and provide advice to businesses and organizations. Engineers are trained in a specific field of engineering, such as mechanical or electrical, and use their knowledge of math, science, and engineering principles to design, build, and maintain a wide range of systems and structures. Consultants, on the other hand, are experts in a particular area of business or management and provide advice and guidance to organizations on a range of topics, such as strategy, operations, and organizational development. Engineers and consultants may specialize in a particular industry or sector. They may also work as part of a team, collaborating with other professionals to deliver projects or solve problems.

With strong skills in mechanical design, piping and framework, energy and technical project management, Cilyx performs comprehensive studies in many industrial sectors.

Thanks to a very diverse sofware suite our team is able to work with the same tools as our customers.