Pre-filled syringes

In order to ensure the authenticity of pharmaceutical products and to fight against the counterfeiting of medicines, marking is a crucial step which allows better control and total traceability of products. This step also makes it possible to eliminate the risks of severe contamination caused by the mix-up of products during filling and packaging operations. But how can we ensure the marking of products without altering the most fragile containers, such as pre-filled syringes and glass vials?

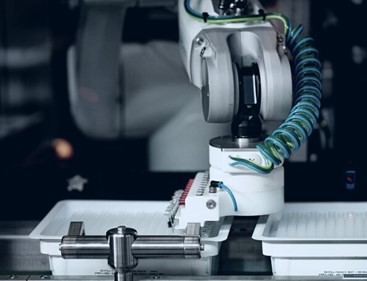

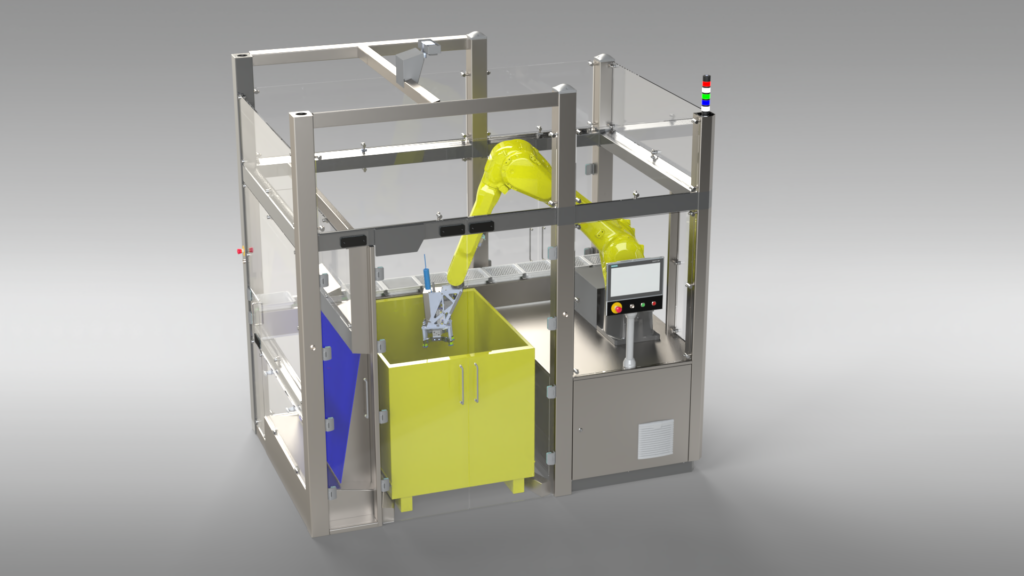

This is now possible with the PFS600.

NAGINELS® technology :

Equipped with innovative NAGINELS® technology, the PFS600 is an exclusive laser-marking solution for pre-filled syringes. It ensures the unique and permanent marking of syringes without altering the glass, in order to offer greater traceability for products and eliminate the risk of mix-ups.