Production Systems

A production system is a set of processes and resources that are used to create goods or services. These systems can be designed to be efficient, flexible, and responsive to changes in demand or market conditions.

There are several different types of production systems. The specific type of production system used in a given situation depends on a variety of factors, including the nature of the product or service being produced, the level of customization required, and the level of demand for the product.

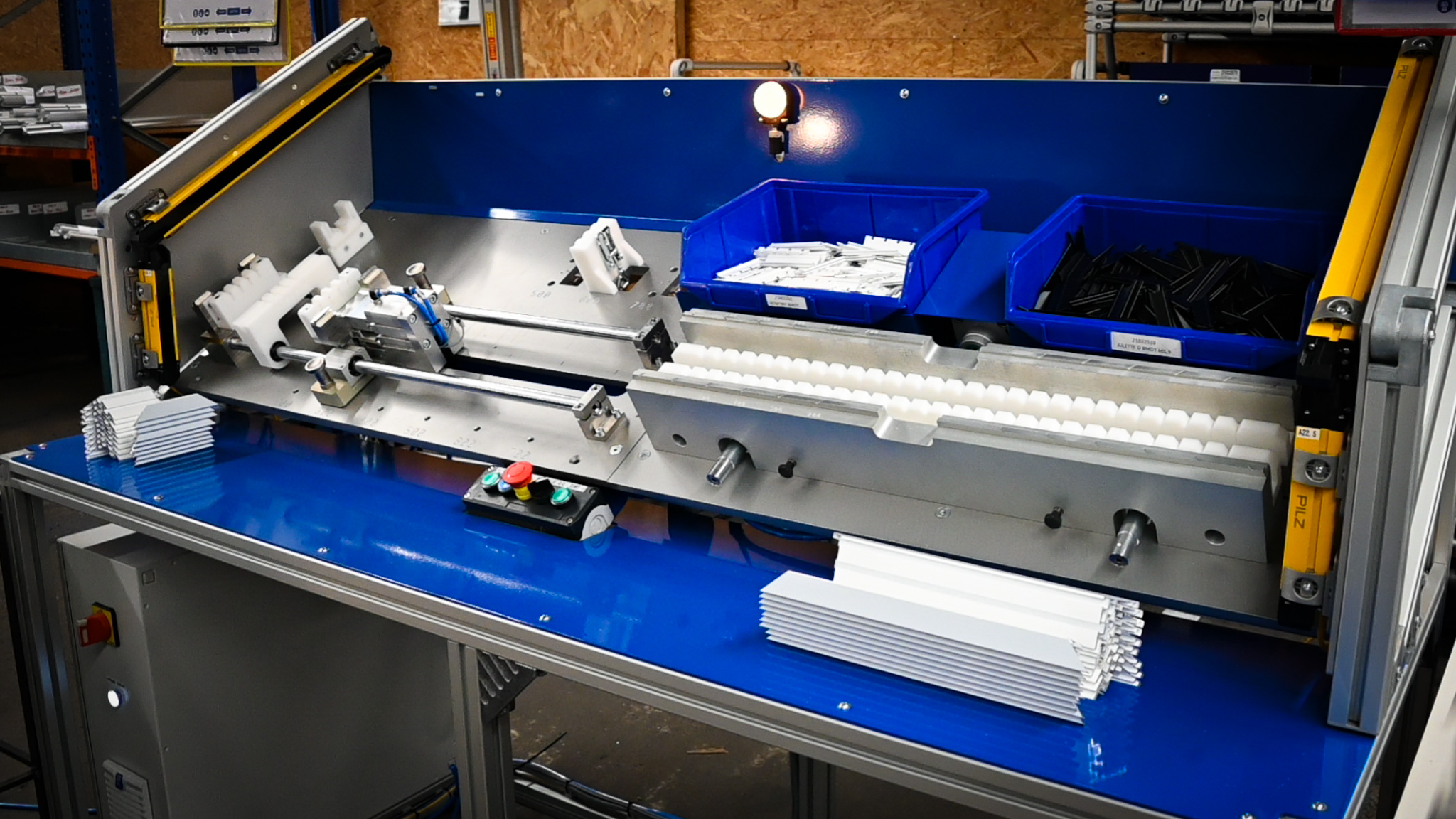

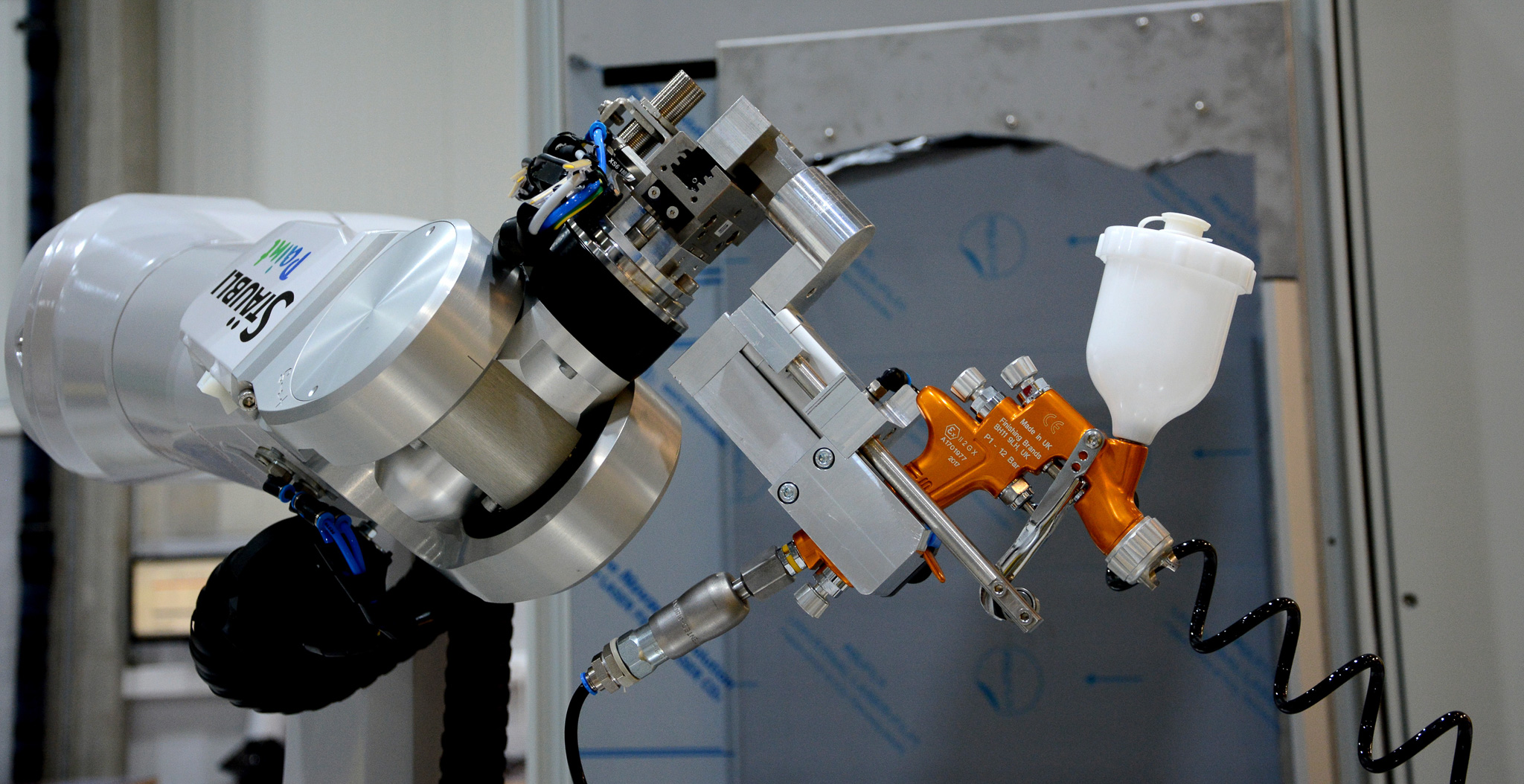

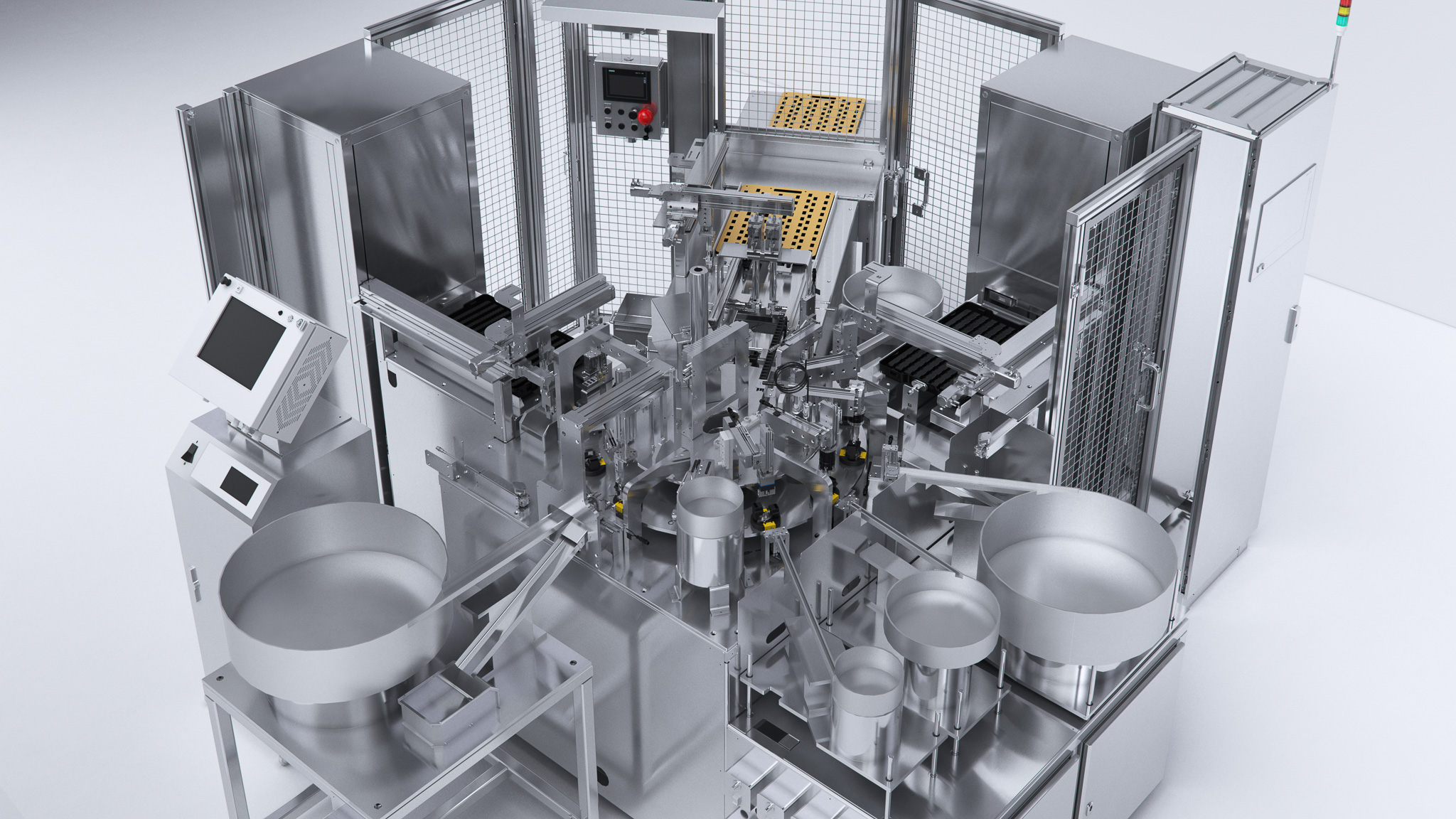

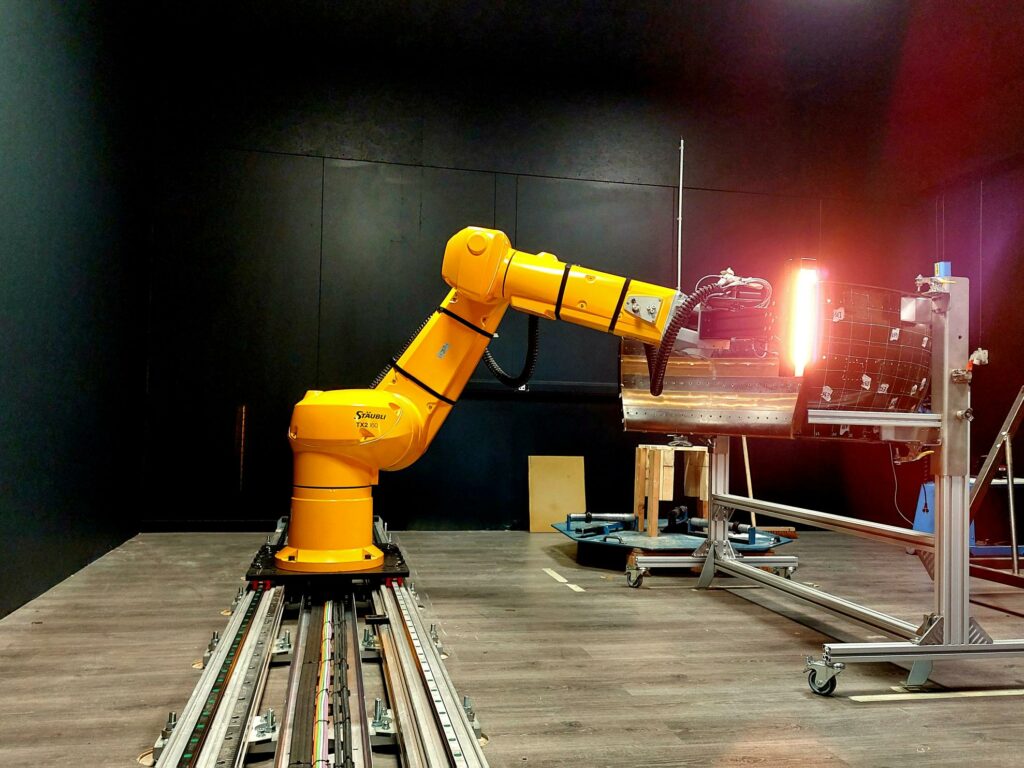

Cilyx develops and integrates “turnkey” production systems and equipment. Thanks to its engineering office and its workshop, Cilyx integrates, tests and qualifies its solutions prior to delivery. Cilyx also develops complex solutions in automated industrial processes thanks to its skills in automation, robotics, electricity, instrumentation, industrial IT and artificial vision.