Implants & Micro-Implants

Implants & Micro-Implants

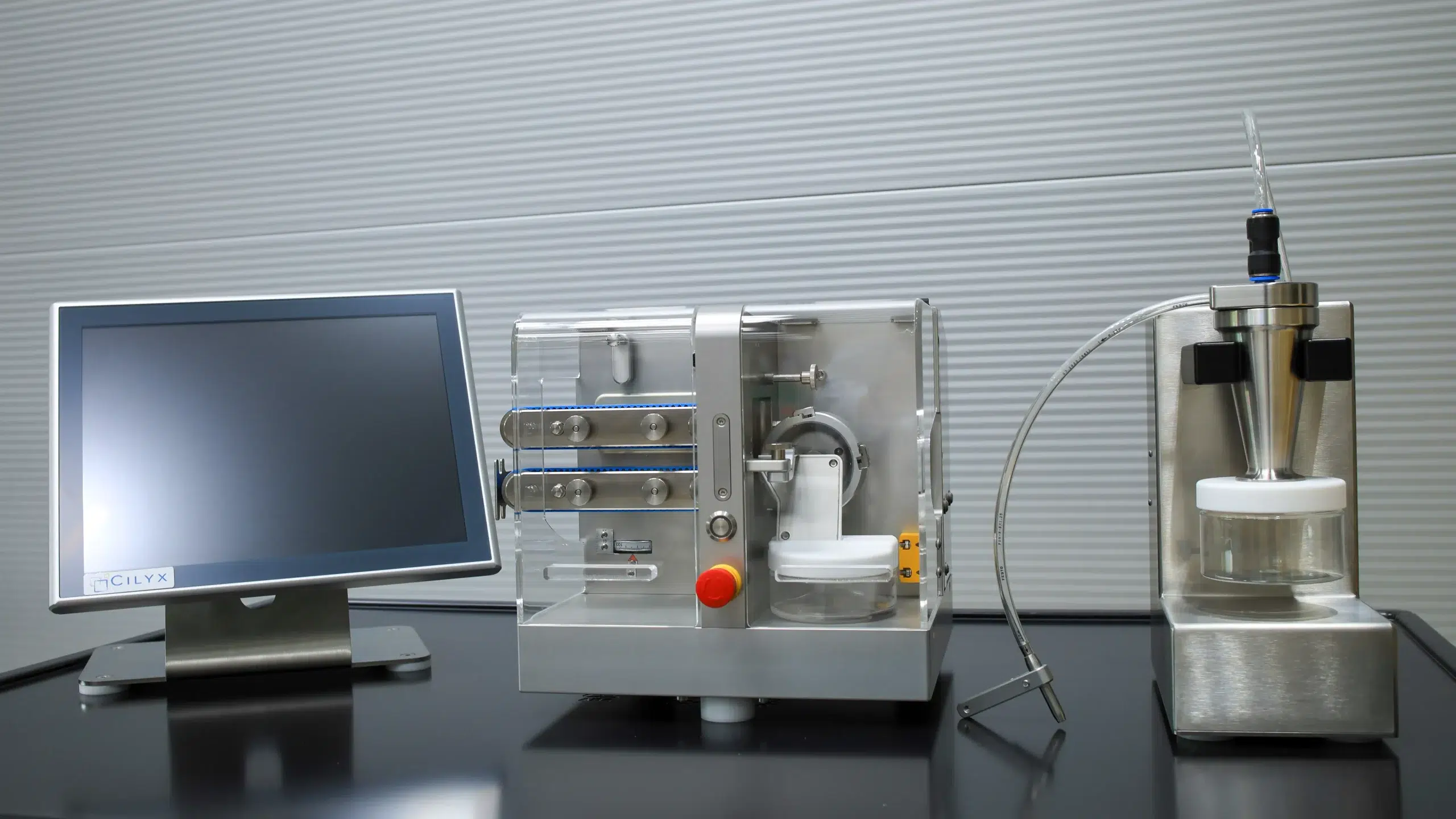

Hot melt extrusion & downstream equipment

Extrusion is an ideal manufacturing technique for preparing several types of dosage forms and drug delivery systems. It offers numerous advantages: the absence of solvents, few processing steps, continuous operation, and the possibility of a solid formulation via controlled and improved diffusion, etc.

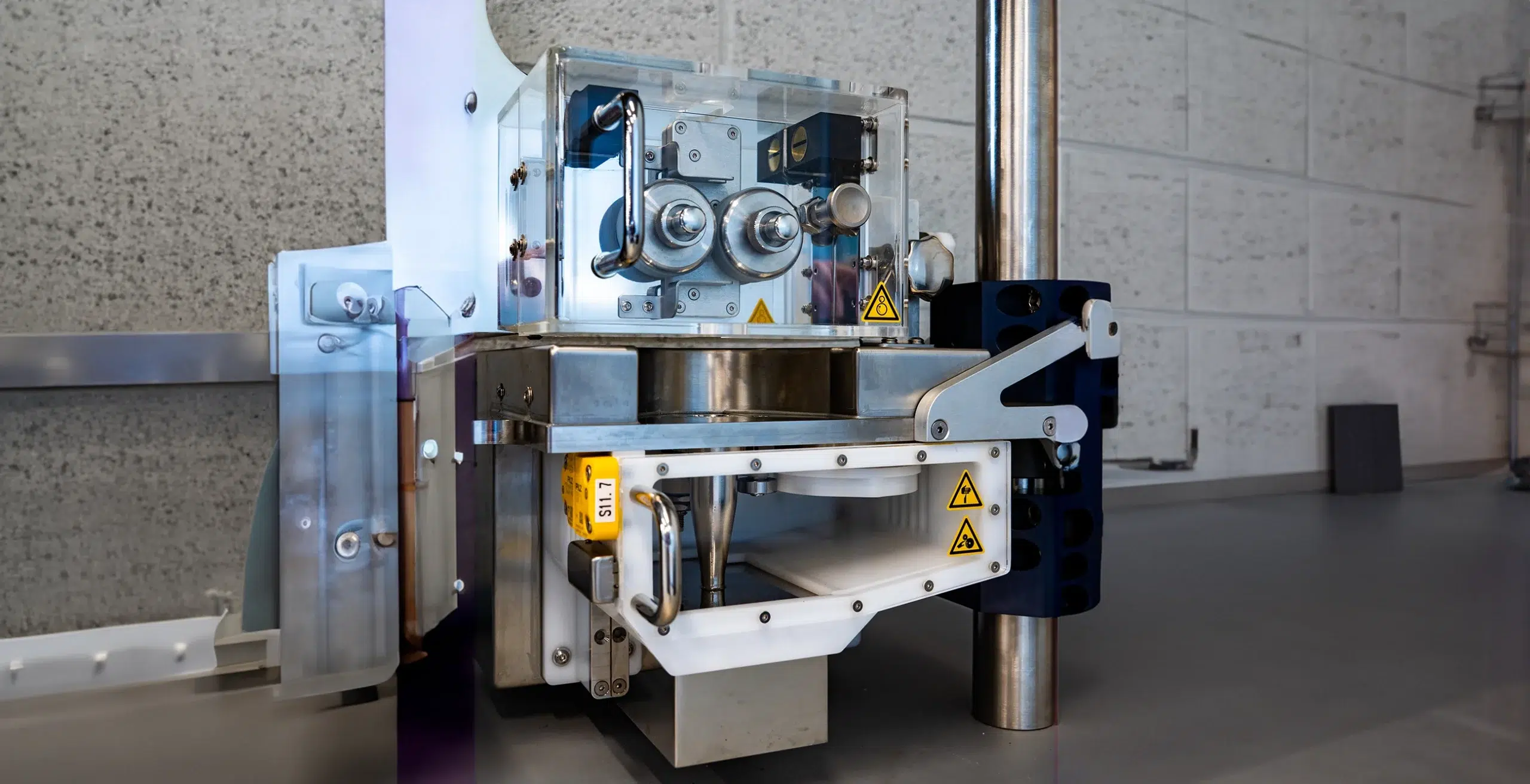

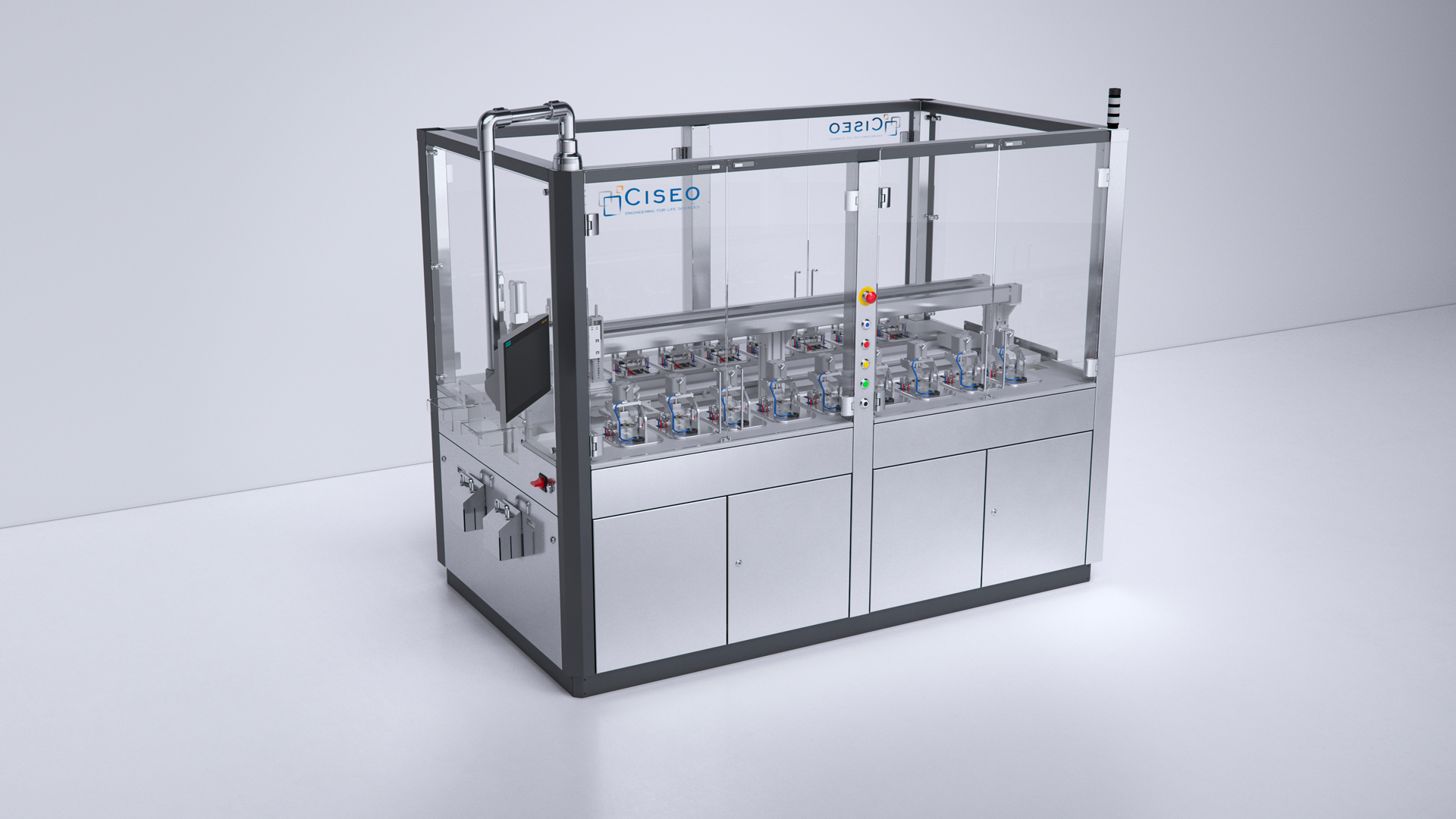

The extruder is usually combined with different types of downstream supplementary equipment, in order to obtain extrusion-based production lines that are capable of manufacturing a variety of solid dosage forms (pellets, tablets, etc.).

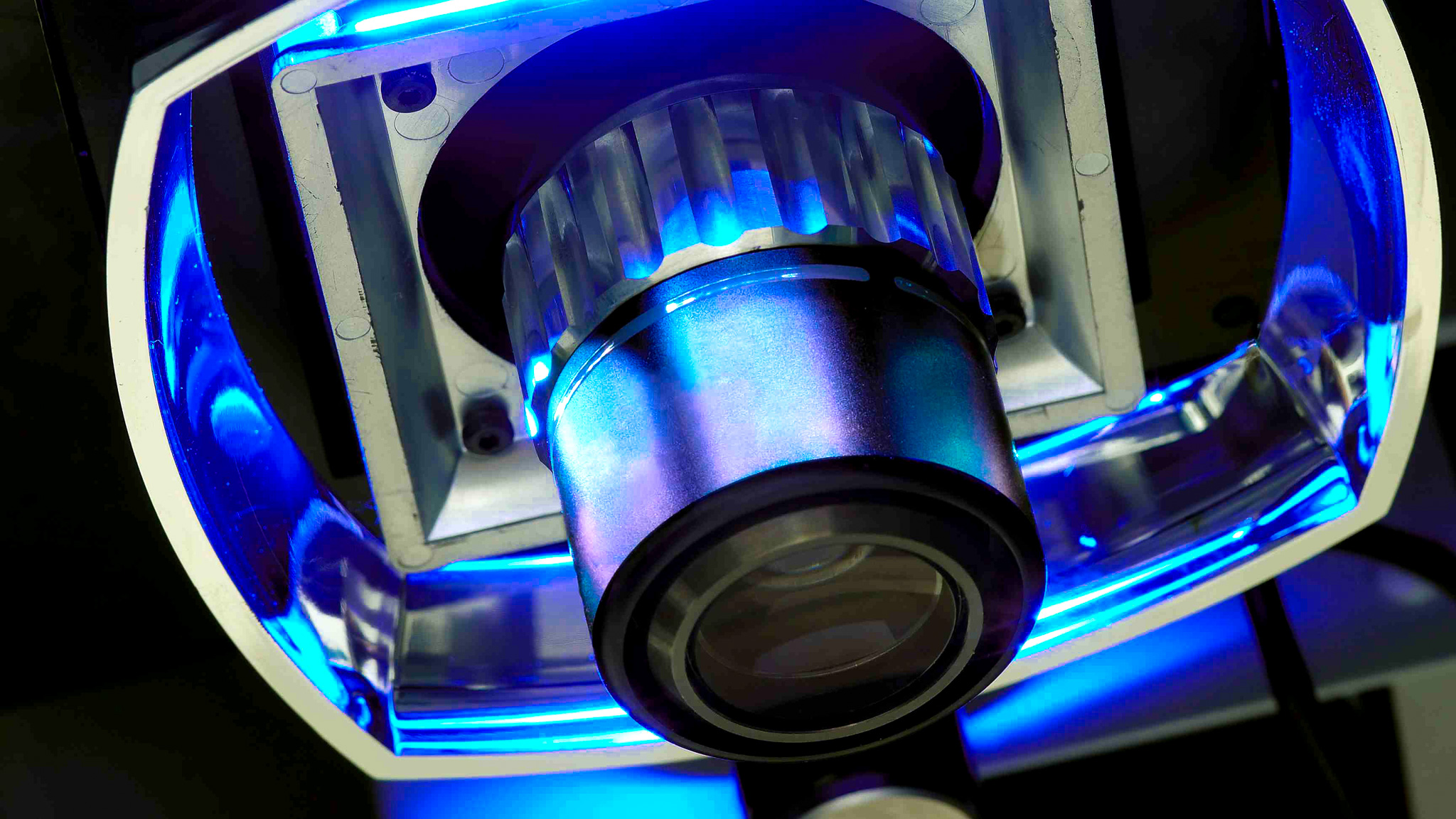

CILYX has developed a variety of supplementary downstream equipment for various pharmaceutical applications, from the laboratory to large-scale production: precision cutting systems (pelletizers), vial cutters, ring-welding solutions, etc.