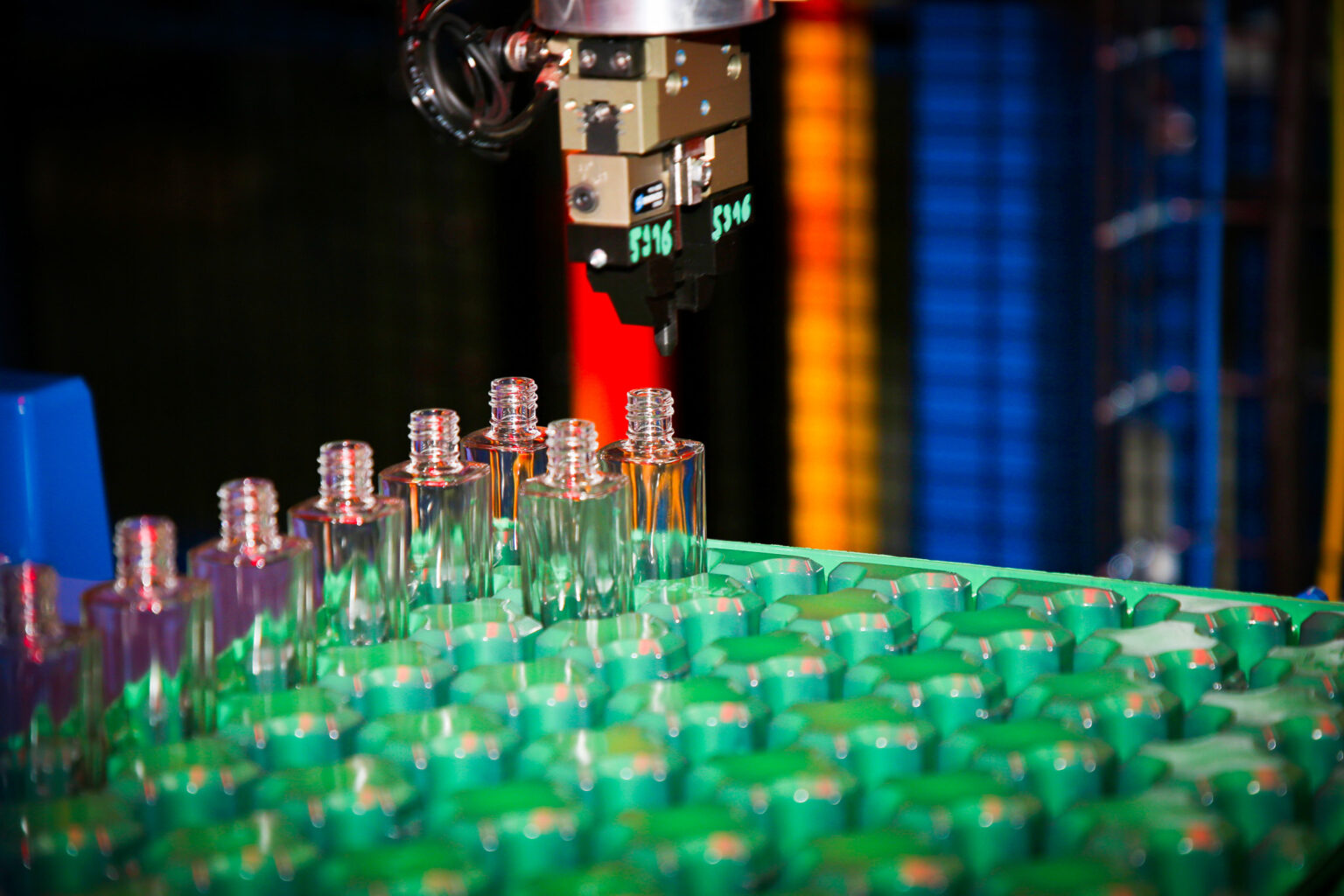

Special machines for handling of products integrated in production lines

Automated handling refers to the use of machines and automation technology to move, sort, or transport materials, components or products. Automated handling systems are designed to improve efficiency, accuracy, and safety, and they are used in a wide range of industries, including manufacturing. Pick and place is a term used to describe the process of selecting and transferring an object from one location to another. This process is often automated using robots or other automation technology.

There are several types of pick and place systems, including:

- Pick and place robots: These are specialized robots that are designed to pick up and place objects with a high degree of precision and speed. They typically use articulated arms or grippers to manipulate the objects.

- Vision-based pick and place systems: These systems use cameras or other sensors to locate and identify objects, and then use robots or other automation technology to pick up and place the objects.

Pick and place systems are widely used in manufacturing and assembly operations to handle a variety of different objects, including components, finished products, and packaging materials. They can significantly improve efficiency and productivity, and they can also reduce the need for manual labor.