Sorting & Recycling

Sorting and recycling are important processes that help to conserve resources and reduce waste. Sorting is the process of separating materials or items into different groups based on their characteristics, such as their size, shape, or composition. This is often done to prepare materials for recycling or disposal.

Recycling is the process of converting materials that would otherwise be discarded into new products. It helps to conserve natural resources, such as trees and minerals, and reduce the environmental impact of waste by reducing the need to extract and process raw materials.

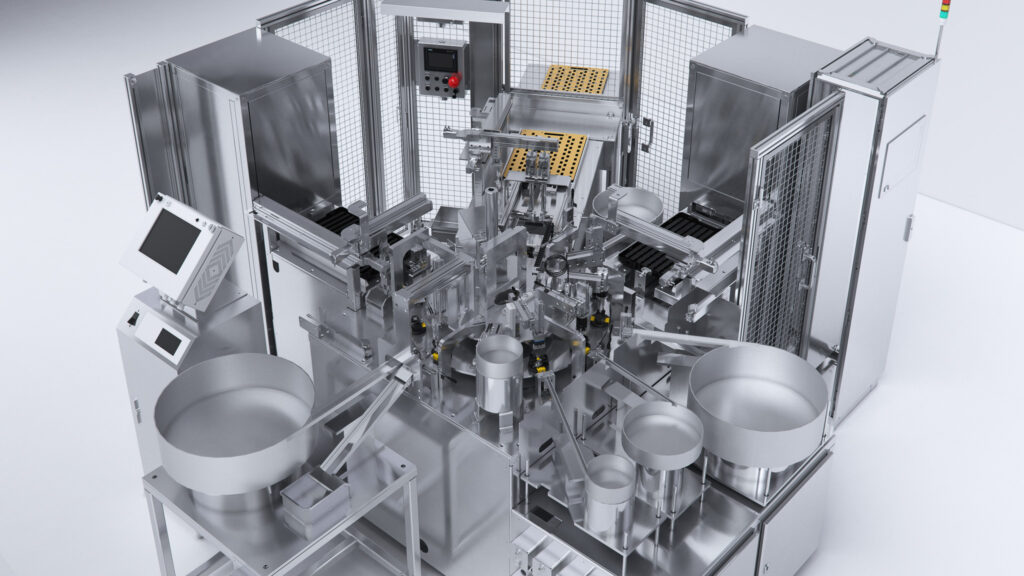

As part of the project Reverse Metallurgy, Cilyx, in collaboration with Comet Treatment and the University of Liège, develops an intelligent high throughput sorting system for characterization of metallic automotive shredder residues for recycling purposes .

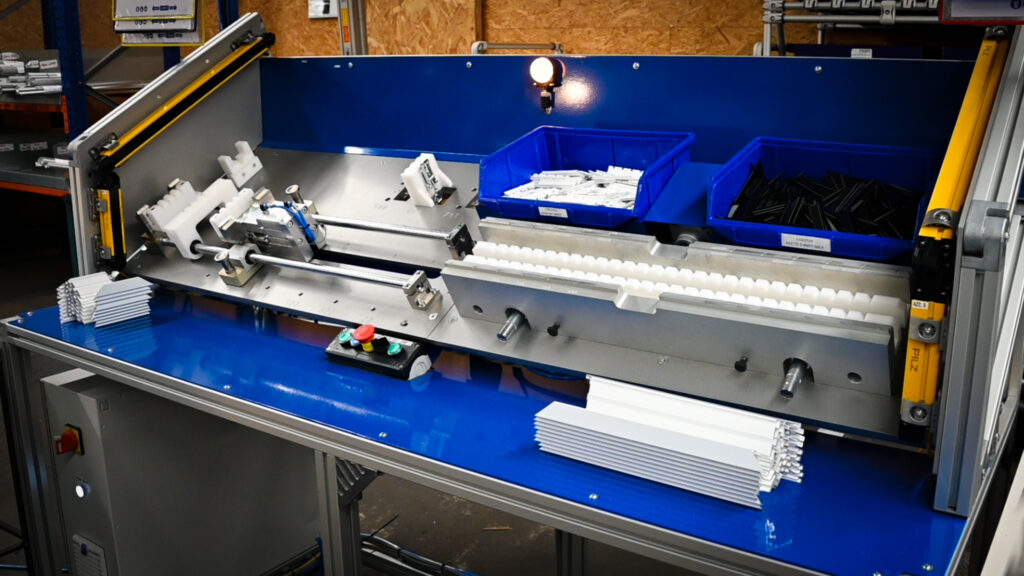

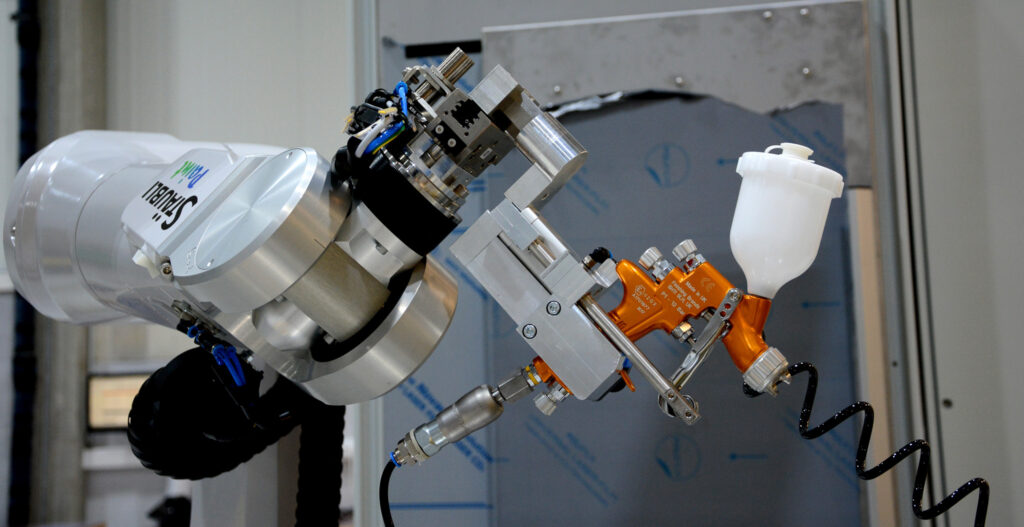

This solution is equiped with various sensors:

This solution allow a real-time high-speed classification of the different metallic objects with help of multiple robots used in parallel.

Take contact with our experts and get personalised advices