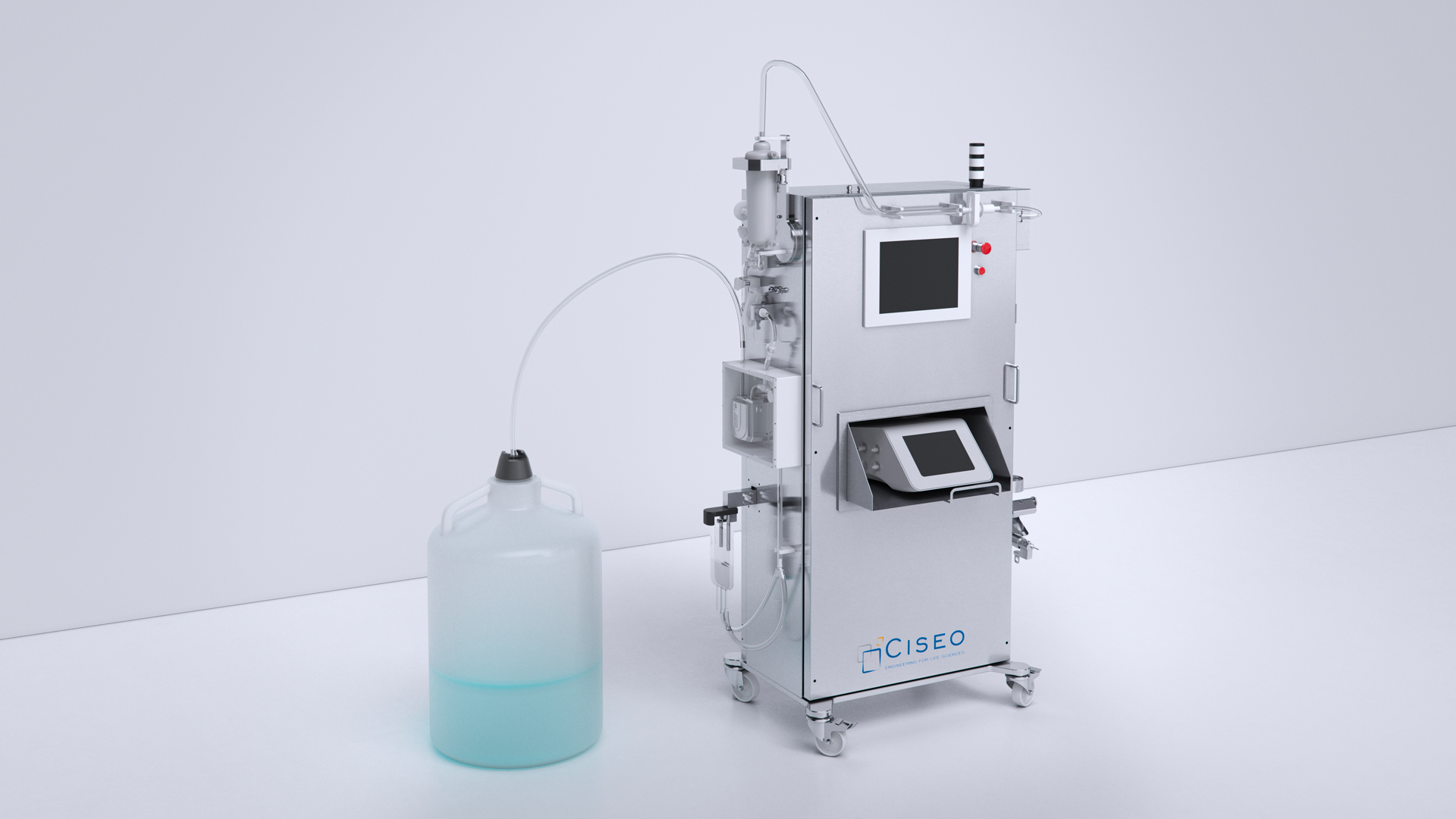

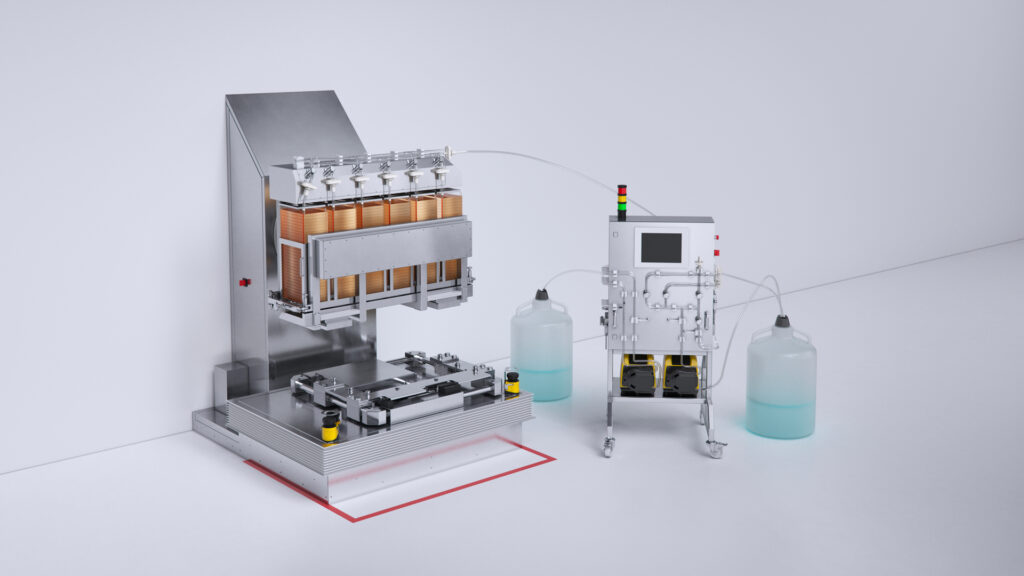

Automation of Single-Use Systems

Sterile filtration of vaccines and parenteral drugs before the filling step is an important requirement in terms of good manufacturing practices in the pharmaceutical sector. You want to make sure that it is carried out under the safest conditions: filter-integrity tests before and after production (PUPSIT – Pre-Use, Post-Sterilization Integrity Testing), sterility assurance and production data integrity are at the heart of the features of our automated AFS V2021 final filtration system.

AFS 2021 automates the transfer and final filtration of your products by adapting to your single-use systems that connect the finished product vessel and your filling equipment. The highly adaptable AFS interfaces with the most common filter-integrity testing equipment and the vast majority of sterile filters on the market.

Benefits

The automated AFS V2021 filtration system perfectly satisfies the needs of the pharmaceutical industries: feedback from production data (batch reports and audit trails) to the customer’s SCADA, compactness, flexibility in the configuration of the single-use assemblies used.

Your filtration system is CE-certified and satisfies all the requirements related to cGMP and GAMP5 good manufacturing practices.